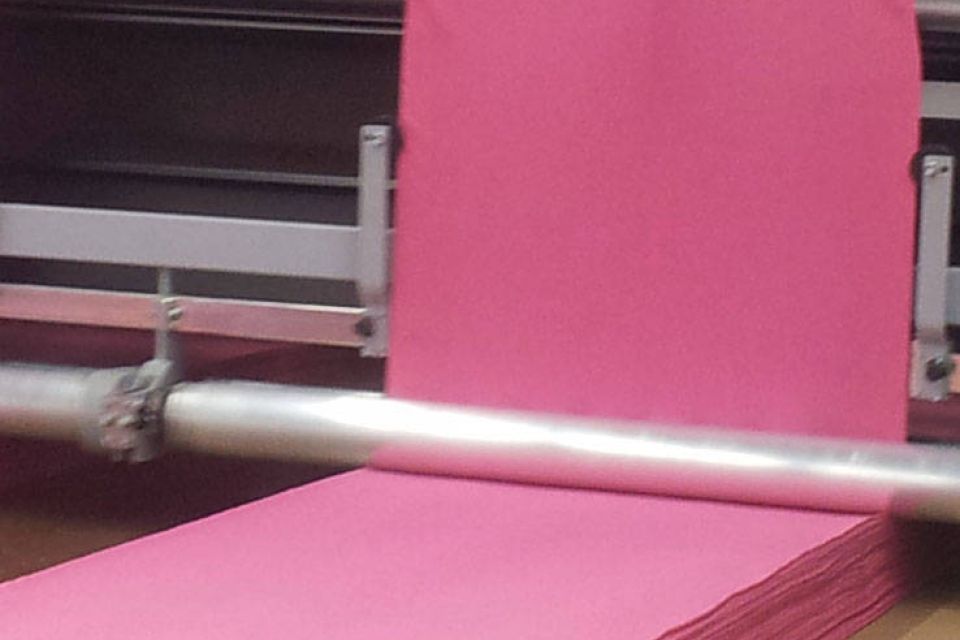

DYNAMIC, flexible fabric and material spreading equipment, robust and compact design, easy to use and low maintenance.

It is equipped with a flexible belt cradle for tension-free spreading of the fabric.

The touch screen makes the programming functions very intuitive and user-friendly. The modularity of the equipment allows the subsequent integration of other available options, adapting at any time to the company's needs.

Available in different widths (imperial and metric), weights and diameters of the rolls.

Materials and applications

Ergonomic with low loading height, quick and effortless roll change.

High speed programmable layer cutter.

The DYNAMIC spreader machine, allows incorporating different optional, zig-zag, tray for stabilized fabric, accordion, open tubular or roll.

Touch screen with intuitive icons, easy to program.

Spread programming: quantities, measurement, accelerations, feeding, splicing points, ...

SYNERGY, programmable, is produced in special widths for the home textile sector.

OTEMAN, has the series SYNERGY very robust spreaders, supporting weights up to 600 kg., specially designed for the denim and workwear sector. For the automotive industry, we have available a large diameter cradle machine, which supports rolls up to 120 cm., ideal for spreading laminated and foamed materials, widely used in the manufacture of ar seats.

Spreading tables: standard, air cushion, conveyor and stackers.

They are built with great precision and in different widths and heights. On the conveyor table, the material is transported by means of a conveyor belt, which ensures that the fabric arrives perfectly aligned and synchronized to the cutter.

Quickloader, automatic roll loading system from floor to cradle.

Solutions for spreading tubular fabrics in rolls or from pallets.

SYNERGY TS, specially developed for tubular fabric spreading, either rolled or folded, the equipment can support up to 400 kg. of weight.

LCS - Cutting room control system.

Wifi communication software that allows centralized management of spreading tasks, verification of material by bar code and the possibility of integrating ERP systems. It generates reports on consumption, hours, etc.